Description

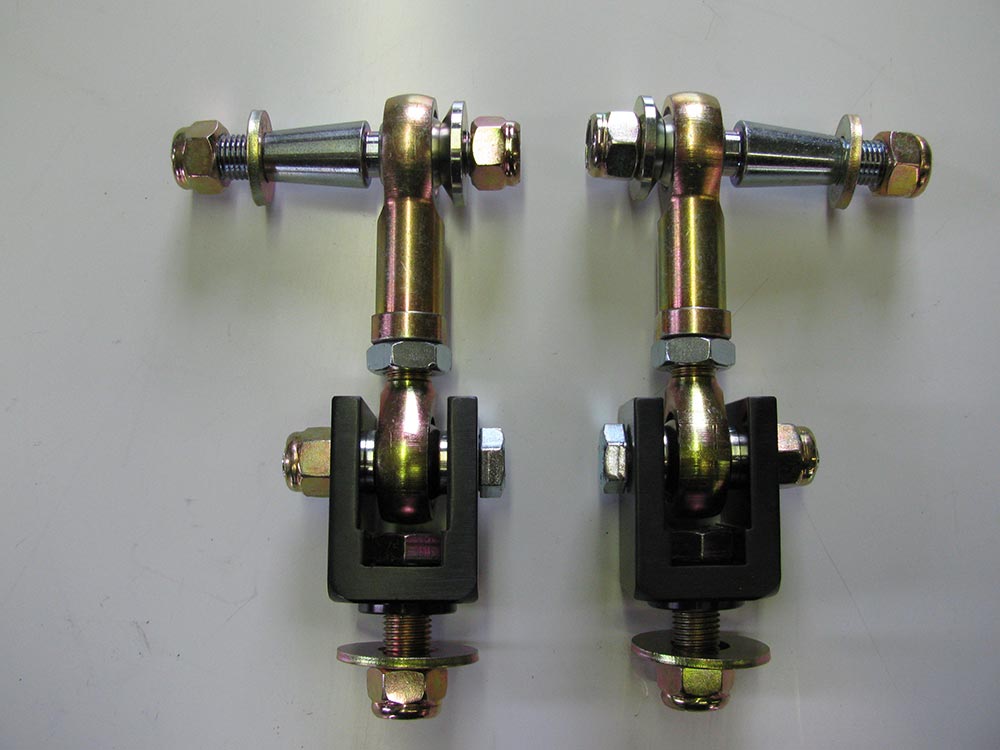

The original type shock links connect to the trailing arm with a rubber bushing above and below the trailing arm. Compression of the soft rubber allows the trailing arm to move up and down a little without moving the shock lever. These spherical rod end links transfer all movement of the trailing arm to the shock lever so the shock can dampen even slight movements of the trailing arm. Replacement original type shock links are prone to failure at the upper end. These upgraded links are a much stronger design that should hold up better than replacement original style links.

Steve Gerow (verified owner) –

Easy installation. Recommend 7/8″ hole saw for enlarging approx 3/4″ hole in swing arm so clevis seats properly per the instructions. Only necessary to drill halfway through. Used Harbor Freight ball joint separator to remove old links from shock arms.

Dave Connitt –

This is a very easy installation. You need to enlarge the lower shock link hole to 7/8” from the top using a step drill. It’s a drop in replacement after that.